A spark-ignition engine, commonly known as an SI engine, stands as the cornerstone of modern vehicular propulsion systems. These engines power millions of cars and vehicles worldwide, converting chemical energy from fuel into mechanical energy through a precisely orchestrated combustion process. Whether you’re driving a compact car or operating a small marine vessel, chances are a spark-ignition engine is working tirelessly under the hood.

What Is a Spark-ignition Engine?

A spark-ignition engine is an internal combustion engine where the fuel-air mixture is ignited by a spark plug. This type of engine primarily runs on gasoline (petrol), but can also operate on alternative fuels like natural gas, propane, ethanol, or even hydrogen. In different regions, these engines may be referred to by various names such as petrol engines, gasoline engines, or Otto cycle engines, named after Nikolaus Otto who invented the four-stroke cycle.

The defining characteristic of a spark-ignition engine is its ignition method—it relies on an electrical spark to initiate combustion, unlike compression-ignition engines (diesel engines) that use heat generated by compression to ignite the fuel. This fundamental difference in ignition mechanism influences the entire design, operation, and performance characteristics of the engine.

SI engines are particularly valued in automotive applications for their smooth operation, higher power-to-weight ratio, and ability to reach higher RPMs compared to their compression-ignition counterparts. Today, they remain the predominant power source for passenger cars worldwide, though their design continues to evolve with advancements in technology and environmental regulations.

What are the main parts of a spark ignition engine?

A spark-ignition engine consists of several critical components that work harmoniously to convert fuel into mechanical energy. Here are the eight main components:

- Inlet Valve: This valve controls the entry of the air-fuel mixture into the cylinder during the intake stroke, opening at precisely the right moment to allow the mixture to flow in.

- Exhaust Valve: This valve manages the exit of combustion gases from the cylinder after the power stroke, expelling burnt gases to make room for a fresh air-fuel mixture.

- Spark Plug: This device delivers the electrical spark that ignites the compressed air-fuel mixture, initiating the combustion process that drives the engine.

- Cylinder: Forms the combustion chamber where the air-fuel mixture burns, typically made of cast iron or aluminum with exceptional heat resistance properties.

- Piston: Moves up and down within the cylinder, compressing the air-fuel mixture and transferring the energy from combustion to the crankshaft via the connecting rod.

- Connecting Rod: Links the piston to the crankshaft, converting the piston’s linear motion into the rotational motion of the crankshaft.

- Crankshaft: Transforms the linear motion of the pistons into rotational motion, ultimately delivering power to the car’s drivetrain.

- Cylinder Head: Seals the top of the cylinder and houses the valves, spark plugs, and parts of the fuel injection system, playing a crucial role in managing combustion.

These components work in precise synchronization, enabling the engine to generate power efficiently and reliably, making it the preferred choice for millions of vehicles on the road today.

How does a spark ignition engine work?

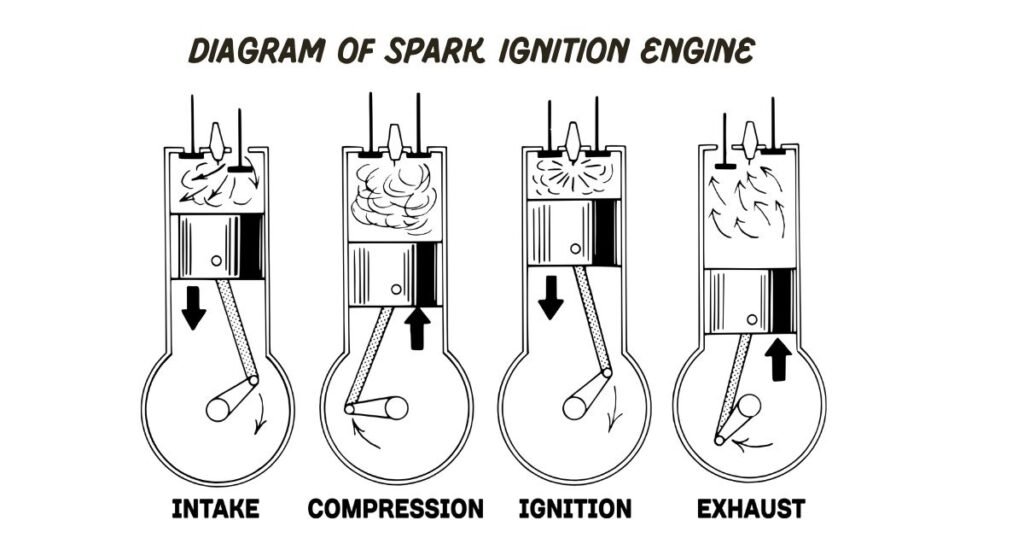

The spark ignition engine operates on a meticulously coordinated four-stroke cycle, each stroke representing a specific phase in the combustion process. This cycle is fundamental to how cars and many other vehicles generate power.

The Four-Stroke Cycle

- Intake Stroke: The process begins with the piston moving downward as the intake valve opens, creating a vacuum that draws the air-fuel mixture into the cylinder. During this stroke, the crankshaft rotates 180 degrees.

- Compression Stroke: Next, both valves close as the piston moves upward, compressing the air-fuel mixture to roughly one-eighth to one-tenth of its original volume. This compression increases the mixture’s temperature and pressure, making it more combustible. The crankshaft completes another 180-degree rotation during this stroke.

- Power Stroke: When the piston reaches the top of its travel (Top Dead Center or TDC), the spark plug fires, igniting the compressed mixture. The resulting explosion forces the piston downward, generating power that’s transferred to the crankshaft. This represents the third 180-degree rotation of the crankshaft.

- Exhaust Stroke: Finally, the exhaust valve opens as the piston moves upward again, pushing the burnt gases out of the cylinder. This completes the cycle with the crankshaft having rotated a full 720 degrees (two complete revolutions).

This four-stroke cycle occurs thousands of times per minute in a running engine, with each cylinder firing in a carefully timed sequence to ensure smooth operation and consistent power delivery.

While most modern cars use four-stroke engines, some smaller vehicles and tools employ two-stroke spark ignition engines, which complete the entire cycle in just one crankshaft revolution. These engines combine the intake and compression strokes, as well as the power and exhaust strokes, making them simpler but generally less efficient and more polluting than their four-stroke counterparts.

The precision timing of valve opening and closing, along with the exact moment of spark delivery, is critical for optimal engine performance. Modern cars use sophisticated electronic control units (ECUs) to manage these parameters, adjusting them in real time based on driving conditions, load requirements, and environmental factors.

What is the function of a piston in a spark ignition engine?

The piston serves as the dynamic heart of the spark ignition engine, performing several critical functions essential to the engine’s operation. As a cylindrical component that moves up and down within the engine cylinder, the piston directly converts the energy released during combustion into mechanical motion.

Primarily, the piston creates the variable volume necessary for the engine’s operation. During the intake stroke, it moves downward to create a vacuum that draws in the air-fuel mixture. Then, during the compression stroke, it moves upward to compress this mixture, increasing its temperature and pressure to optimize combustion efficiency.

When the spark plug ignites the compressed mixture, the resulting explosion forces the piston downward during the power stroke. This downward motion transfers energy to the crankshaft via the connecting rod, generating the rotational force that ultimately powers the car’s wheels.

Additionally, the piston functions as a mobile seal, working in conjunction with piston rings to prevent combustion gases from escaping past the sides of the piston into the crankcase. This sealing action is crucial for maintaining compression and ensuring the engine’s efficient operation.

The piston also plays a thermal role, absorbing and dissipating some of the extreme heat generated during combustion. Modern pistons are precision-engineered components, typically made from aluminum alloys with specific thermal expansion properties to maintain optimal clearances at operating temperatures.

What does the cylinder head do in a spark ignition engine?

The cylinder head is the critical upper structural component of the spark ignition engine. It seals the top of the cylinder and houses several essential engine components. This multifunctional element plays a decisive role in the combustion process and overall engine performance.

Primarily, the cylinder head forms the upper portion of the combustion chamber, where the controlled explosion of the air-fuel mixture occurs. Its precision-engineered design significantly influences the combustion efficiency and power output of the engine.

As an integral component of the thermal management system, the cylinder head contains internal passages for coolant circulation. These passages facilitate heat dissipation from the combustion chamber, preventing overheating and maintaining optimal operating temperatures for enhanced performance and longevity.

The cylinder head houses the valvetrain components, including the intake and exhaust valves, valve springs, retainers, and often the camshaft in overhead cam designs. These components control the flow of air-fuel mixture into the cylinder and the expulsion of exhaust gases, directly impacting the engine’s breathing capability and efficiency.

Additionally, the cylinder head incorporates mounting points for the spark plugs, positioning them optimally to ignite the compressed air-fuel mixture at precisely the right moment. In modern engines, it also accommodates fuel injectors, sensors, and other electronic components that monitor and control the combustion process.

The design of the cylinder head—particularly the shape of the combustion chamber and the layout of the intake and exhaust ports—significantly affects the engine’s power output, fuel efficiency, and emissions characteristics. Engineers meticulously optimize these parameters to achieve the desired balance of performance, economy, and environmental compliance.

How does the spark plug function in an SI engine?

The spark plug serves as the critical ignition component in a spark ignition engine, delivering the electrical spark that initiates combustion. This seemingly simple device plays a sophisticated role in the precise timing and control of the engine’s power generation process.

At its core, the spark plug consists of a center electrode and a ground electrode separated by a precisely calibrated gap. When the engine’s ignition system sends a high-voltage electrical current (typically 20,000 to 100,000 volts) to the spark plug, it creates an electrical arc across this gap. This momentary arc, lasting only a fraction of a millisecond, provides the activation energy needed to ignite the compressed air-fuel mixture.

The timing of this spark is meticulously controlled by the engine’s electronic control unit (ECU), which adjusts ignition timing based on multiple factors, including engine speed, load, temperature, and atmospheric conditions. This precise timing ensures optimal combustion efficiency and power output across different operating conditions.

Modern spark plugs incorporate sophisticated materials and designs to withstand the extreme conditions inside the combustion chamber. The center electrode often contains precious metals like platinum or iridium to improve conductivity and longevity, while the insulator (typically ceramic) prevents the high-voltage current from short-circuiting.

The spark plug also functions as a thermal management device, with its heat range carefully selected to match the engine’s operating characteristics. A spark plug that runs too hot can cause pre-ignition or damage to engine components, while one that runs too cold may accumulate carbon deposits that interfere with proper operation.

Additionally, the condition of the spark plug provides valuable diagnostic information about the engine’s health. Examining the color and condition of the deposits on a used spark plug can reveal issues such as improper air-fuel mixture, oil consumption, or overheating.

What is the role of the crankshaft in a spark ignition engine?

The crankshaft functions as the mechanical cornerstone of the spark ignition engine, converting the linear motion of the pistons into the rotational motion that ultimately powers the vehicle. This precision-engineered component essentially transforms the up-and-down movement resulting from combustion into the circular motion required to propel the car forward.

Structurally, the crankshaft features offset sections called “throws” or “crankpins” that connect to the pistons via connecting rods. As the pistons move up and down within their cylinders, they rotate these throws, causing the entire crankshaft to spin. This rotation is then transferred to the transmission and ultimately to the wheels, providing the driving force for the vehicle.

Beyond its primary function of motion conversion, the crankshaft also synchronizes the operating cycles of the various engine components. Its precise design ensures that each piston reaches the top and bottom of its stroke at precisely the right moment, maintaining the correct timing sequence for intake, compression, power, and exhaust strokes across all cylinders.

Modern crankshafts incorporate counterweights that balance the rotating assembly, reducing vibration and ensuring smooth operation. They also feature precision-machined bearing surfaces that minimize friction while withstanding the enormous forces generated during combustion.

The crankshaft works in concert with the flywheel, which stores rotational energy to maintain momentum between power strokes and smooth out power delivery. Together, these components form the heart of the engine’s mechanical system, translating the energy of combustion into the smooth, continuous power that drives the vehicle.

How do intake and exhaust valves work in an SI engine?

The intake and exhaust valves function as precision-engineered gatekeepers in a spark ignition engine, meticulously timing the flow of gases into and out of the combustion chamber. These components play a critical role in determining the engine’s breathing efficiency, power output, and emissions characteristics.

Intake Valve Operation

The intake valve controls the entry of the air-fuel mixture into the cylinder. During the intake stroke, as the piston moves downward, the intake valve opens, creating a pathway for the mixture to flow into the expanding cylinder. The valve’s opening is precisely timed to maximize cylinder filling, typically beginning slightly before the piston reaches the top dead center (TDC) of the exhaust stroke and closing after the piston passes the bottom dead center (BDC) of the intake stroke.

This slight overlap in timing, known as “valve overlap,” helps improve cylinder filling by using the inertia of moving gases to enhance the scavenging of exhaust gases and the intake of fresh mixture. The exact timing and duration of intake valve opening (measured in degrees of crankshaft rotation) significantly impact the engine’s performance characteristics, particularly at different RPM ranges.

Exhaust Valve Operation

The exhaust valve manages the exit of combustion gases from the cylinder. After the power stroke, as the piston moves upward, the exhaust valve opens, allowing the pressure in the cylinder to expel the burnt gases. Like the intake valve, the exhaust valve’s operation is precisely timed—opening before the piston reaches the BDC of the power stroke and closing after the piston passes the TDC of the exhaust stroke.

Valve Actuation Mechanisms

Camshafts typically actuate both intake and exhaust valves, either directly or through intermediate components like rocker arms or push rods. The camshaft’s lobes determine the timing, duration, and lift (how far the valve opens) of each valve event. Modern engines often employ variable valve timing (VVT) systems that can adjust these parameters based on engine speed and load conditions, optimizing performance across a wider operating range.

The valves themselves are precision components designed to withstand extreme temperatures and pressures. Intake valves generally have larger heads than exhaust valves to facilitate better cylinder filling. Exhaust valves, which endure higher temperatures, are often made from more heat-resistant materials and may incorporate sodium-filled stems for improved heat dissipation.

What is the function of a carburetor in a spark ignition engine?

A carburetor is a mechanical device that mixes air and fuel in the correct proportions for combustion in a spark-ignition engine. While modern cars have largely transitioned to electronic fuel injection systems, carburetors were the standard fuel delivery method for spark-ignition engines for many decades and are still used in some small engines and classic vehicles today.

At its core, a carburetor operates on the Venturi principle, where air passing through a restriction (the Venturi tube) increases in velocity and decreases in pressure. This pressure drop draws fuel from a reservoir (the float bowl) through carefully calibrated jets and into the airstream, creating a combustible mixture that’s delivered to the engine’s cylinders.

The primary function of a carburetor in a spark ignition engine is to maintain the optimal air-fuel ratio across varying engine speeds and load conditions. For gasoline engines, this ideal ratio is approximately 14.7:1 (air to fuel by weight), often called the stoichiometric ratio. However, different operating conditions may require richer or leaner mixtures.

Carburetors incorporate several systems to address these varying needs:

- The idle circuit provides a richer mixture for stable operation at low speeds when the throttle is nearly closed.

- The main circuit delivers fuel during regular operation, with the amount determined by the size of the main jet and the airflow through the Venturi.

- The acceleration pump provides a momentary rich mixture when the throttle opens quickly, preventing hesitation during acceleration.

- The choke restricts airflow when starting a cold engine, creating a richer mixture that improves cold-start performance.

Despite their mechanical simplicity, carburetors require precise calibration and adjustment to maintain optimal performance. They can be sensitive to altitude changes, temperature variations, and wear over time, which affects their ability to keep the ideal air-fuel ratio.

With the advent of stricter emissions regulations and demands for improved fuel efficiency, electronic fuel injection systems have replaced mainly carburetors in modern vehicles. These systems offer more precise fuel metering, better cold-start performance, reduced emissions, and improved fuel economy compared to carbureted engines.

What are the differences between a spark ignition and a compression ignition engine?

Spark ignition (SI) engines and compression ignition (CI) engines represent the two primary types of internal combustion engines used in vehicles today. While they share some basic principles, their fundamental operating mechanisms and characteristics differ significantly.

| Characteristic | Spark Ignition Engine | Compression Ignition Engine |

| Ignition Method | Uses a spark plug to ignite the air-fuel mixture | Relies on heat generated by compression to ignite the fuel |

| Fuel Type | Primarily gasoline/petrol, but can use natural gas, propane, ethanol | Primarily diesel fuel |

| Compression Ratio | Lower (8:1 to 12:1) | Higher (14:1 to 25:1) |

| Fuel Delivery | Premixed air-fuel mixture before compression | Air compressed first, then fuel injected |

| Throttle Control | Controls power by varying the amount of air-fuel mixture | Controls power by varying the amount of fuel injected |

| Air-Fuel Ratio | Operates near stoichiometric ratio (14.7:1) | Operates with excess air (lean mixture) |

| Efficiency | Generally lower thermal efficiency | Higher thermal efficiency |

| Power Characteristics | Higher power-to-weight ratio, higher RPM capability | Higher torque at lower RPM |

| Emissions | Typically lower particulate matter but higher NOx emissions | Higher particulate matter but can have lower NOx emissions |

| Noise Level | Generally quieter operation | Typically louder operation |

| Cold Starting | Easier to start in cold conditions | More difficult to start when cold, may require glow plugs |

| Cost | Generally less expensive to manufacture | Usually more expensive to manufacture |

The fundamental difference—the ignition method—dictates many of the other distinctions. SI engines in cars rely on precisely timed sparks to ignite a homogeneous air-fuel mixture, while CI engines inject fuel directly into highly compressed, hot air, causing spontaneous ignition.

These differences make each engine type suitable for different applications. SI engines typically power passenger cars where smooth operation, higher RPM capability, and lower cost are priorities. CI engines are often preferred for heavy-duty applications, trucks, and vehicles where fuel efficiency and torque are more important than high-speed operation.

How does the fuel injection system work in a spark ignition engine?

The fuel injection system in a spark ignition engine is a sophisticated method of delivering precisely measured amounts of fuel to the engine at exactly the right moment. Due to its superior accuracy, efficiency, and emissions control capabilities, this system has largely replaced carburetors in modern cars.

At its core, a fuel injection system atomizes the fuel by forcing it through small nozzles under pressure, creating a fine mist that mixes efficiently with the incoming air. This process optimizes combustion by ensuring proper fuel distribution and promoting complete burning of the fuel-air mixture.

In modern spark ignition engines, there are several types of fuel injection systems:

- Port Fuel Injection (PFI): The most common type in gasoline cars until recently, where fuel is injected into the intake port just before the intake valve. The injector sprays fuel in precise pulses, timed to coincide with the intake valve opening. This creates a homogeneous air-fuel mixture that enters the cylinder during the intake stroke.

- Direct Injection (DI): An increasingly popular technology where fuel is injected directly into the combustion chamber, similar to diesel engines. This allows for more precise control over the injection timing and fuel distribution, enabling higher compression ratios and potentially improving both power and fuel economy.

- Throttle Body Injection (TBI): An older, simpler system where one or two injectors are located in the throttle body, spraying fuel into the intake manifold. While less precise than other methods, it represented an important step in the evolution from carburetors to modern injection systems.

The operation of these systems is controlled by the engine’s electronic control unit (ECU), which continuously monitors various sensors including:

- Mass airflow sensors that measure the amount of air entering the engine

- Oxygen sensors that analyze exhaust composition to determine if the air-fuel ratio is optimal

- Engine temperature sensors that help adjust the mixture for different operating conditions

- Throttle position sensors that detect driver demand

Based on these inputs, the ECU calculates the precise amount of fuel needed and sends electrical signals to the injectors, controlling both the timing and duration of the injection. This closed-loop control system continuously adjusts the fuel delivery to maintain the optimal air-fuel ratio across all operating conditions, maximizing performance, fuel economy, and emissions control.

Fuel injection systems have evolved, driven by increasingly stringent emissions standards and demands for better fuel efficiency. Modern systems can adjust injection patterns multiple times during a single combustion cycle, providing unprecedented control over the combustion process in spark ignition engines.

What materials are used for spark ignition engine parts?

The materials used in spark ignition engine components represent a careful balance between performance requirements, durability, weight considerations, thermal properties, and manufacturing costs. Modern engines rely on sophisticated materials science to meet increasingly demanding specifications for efficiency, emissions, and longevity.

Engine Block and Cylinder

- Cast Iron: Traditionally used for engine blocks due to its excellent wear resistance, thermal stability, and damping properties. Still common in some applications where weight is less critical.

- Aluminum Alloys: Now predominant in passenger car engines, offering significant weight reduction (typically 50% lighter than cast iron). These alloys usually contain silicon, copper, and magnesium to improve strength and heat resistance. Many aluminum blocks feature cast iron cylinder liners for improved durability.

- Aluminum-Silicon Alloys: Used in some high-performance applications, allowing for cylinder bores without separate liners.

Cylinder Head

- Aluminum Alloys: Most common in modern cars, offering excellent heat dissipation properties and reduced weight.

- Cast Iron: Still used in some heavy-duty applications where durability under extreme conditions is prioritized over weight.

Pistons

- Aluminum Alloys: Standard for pistons due to their low weight and good thermal expansion characteristics. Often contain silicon to reduce thermal expansion and improve strength at high temperatures.

- Forged Aluminum: Used in high-performance applications, offering greater strength than cast pistons.

- Steel: Occasionally used in heavy-duty or racing applications where extreme durability is required.

Connecting Rods

- Forged Steel: Common in production cars, offering excellent strength and durability.

- Titanium Alloys: Used in high-performance and racing engines, offering exceptional strength-to-weight ratio.

- Aluminum Alloys: Sometimes used in lighter-duty applications to reduce reciprocating mass.

Crankshaft

- Forged Steel: Preferred for durability and strength in most applications.

- Cast Iron: Used in some lower-cost applications.

- Billet Steel: Found in high-performance engines, offering maximum strength.

Valves

- Stainless Steel: Commonly used for intake valves.

- Nickel-Chromium Alloys: Often used for exhaust valves to withstand higher temperatures.

- Titanium: Used in high-performance applications for reduced weight and improved valve train dynamics.

- Inconel: A superalloy used in extreme-duty exhaust valves for its exceptional heat resistance.

Valve Springs

- Silicon-Chromium Steel: Standard material offering good fatigue resistance.

- Titanium: Used in high-performance applications for reduced weight and higher natural frequency.

Spark Plugs

- Copper Core: Traditional design offering good conductivity.

- Platinum or Iridium Tips: Used in modern plugs for improved longevity and performance.

- Ceramic Insulators: Provide electrical isolation and thermal stability.

The ongoing development of materials for spark ignition engines focuses on reducing weight while maintaining or improving durability. Advanced materials like metal matrix composites, ceramic components, and carbon fiber-reinforced polymers are increasingly finding applications in specialized areas of engine design, particularly in high-performance and racing engines where cost constraints are less restrictive.

What are the common problems in spark ignition engine components?

Spark ignition engines, despite their sophisticated design and engineering, can develop various issues that affect performance, efficiency, and reliability. Understanding these common problems helps car owners identify potential issues early and take appropriate action before they lead to more significant damage.

Ignition System Issues

- Fouled Spark Plugs: Carbon deposits, oil contamination, or fuel additives can coat spark plug electrodes, reducing their ability to produce a strong spark. Symptoms include rough idling, difficult starting, and reduced fuel economy.

- Ignition Coil Failure: When ignition coils deteriorate, they cannot generate sufficient voltage for reliable spark production. This commonly results in engine misfires, especially under load or at higher RPMs.

- Damaged Spark Plug Wires: Cracked insulation or high resistance in spark plug wires can cause misfires and power loss. This is less common in modern cars with coil-on-plug designs.

Fuel System Problems

- Clogged Fuel Injectors: Deposits can restrict injector flow or disrupt spray patterns, leading to poor combustion, reduced power, and increased emissions.

- Failing Fuel Pump: When a fuel pump begins to fail, it may not deliver sufficient pressure to the injectors, causing performance issues particularly during acceleration or at higher speeds.

- Contaminated Fuel: Water or debris in fuel can damage injectors and interfere with proper combustion, potentially causing stalling or irregular operation.

Air Intake and Emission Control Issues

- Dirty Air Filter: A clogged air filter restricts airflow to the engine, reducing power and efficiency while potentially causing a rich-running condition.

- Malfunctioning MAF Sensor: The Mass Air Flow sensor measures incoming air; when it fails, the engine may run too rich or too lean, affecting performance and fuel economy.

- EGR System Problems: A stuck or clogged Exhaust Gas Recirculation valve can cause rough idling, stalling, and increased NOx emissions.

Mechanical Components

- Worn Valve Seals or Guides: These can allow oil to enter the combustion chamber, causing blue smoke from the exhaust, fouled spark plugs, and increased oil consumption.

- Piston Ring Wear: Worn rings reduce cylinder compression and allow oil to enter the combustion chamber, resulting in power loss, oil consumption, and increased emissions.

- Timing Chain/Belt Issues: Stretched timing chains or worn belts can alter valve timing, reducing performance and potentially causing catastrophic engine damage if they fail completely.

Cooling System Problems

- Thermostat Failure: A stuck thermostat can cause overheating (if stuck closed) or prevent the engine from reaching optimal operating temperature (if stuck open).

- Water Pump Issues: A failing water pump reduces coolant circulation, potentially leading to overheating and engine damage.

- Radiator Blockage: Scale or debris in the radiator can restrict coolant flow, reducing cooling efficiency.

Oil System Issues

- Oil Sludge: Irregular oil changes can lead to sludge build-up that restricts oil flow to critical components, accelerating wear.

- Oil Pump Failure: When the oil pump fails, engine components receive insufficient lubrication, potentially leading to rapid wear and catastrophic failure.

Addressing these issues promptly through regular maintenance and attentive driving can significantly extend the life of a spark ignition engine and maintain its performance. Modern cars equipped with sophisticated engine management systems can often detect many of these problems and alert drivers through warning lights or messages before severe damage occurs.

What are the Applications of Spark Ignition Engine?

Spark ignition engines have found widespread application across numerous sectors due to their versatility, efficiency, and reliable performance characteristics. Their ability to provide smooth power delivery across a wide RPM range makes them particularly suitable for various uses beyond just passenger cars.

Passenger Vehicles

- Compact and Midsize Cars: The majority of passenger vehicles worldwide use four-stroke SI engines due to their smooth operation, reasonable fuel efficiency, and lower manufacturing costs compared to diesel alternatives.

- Performance and Sports Cars: SI engines’ ability to operate at higher RPMs makes them ideal for performance applications where power density and responsiveness are crucial.

- Luxury Vehicles: Many premium automobiles utilize advanced spark ignition technologies like direct injection and variable valve timing to balance power, refinement, and efficiency.

Motorcycles and Small Recreational Vehicles

- Motorcycles: Both two-stroke and four-stroke SI engines are common, with two-stroke designs found in some smaller motorcycles and four-stroke engines dominating larger models.

- ATVs and Snowmobiles: These recreational vehicles typically use SI engines due to their favorable power-to-weight ratio and ability to operate in various environmental conditions.

- Personal Watercraft: Many jet skis and small watercraft utilize two-stroke SI engines, though environmental regulations are driving a shift toward four-stroke designs.

Marine Applications

- Outboard Motors: Smaller boats commonly use outboard motors powered by spark-ignition engines, which range from small portable units to larger multi-cylinder engines.

- Personal Boats: Pleasure craft and smaller fishing boats frequently employ SI engines due to their lighter weight compared to diesel alternatives.

Small Equipment and Tools

- Lawn and Garden Equipment: Lawnmowers, leaf blowers, chainsaws, and trimmers typically use small single-cylinder SI engines, often in two-stroke configurations for handheld applications.

- Portable Generators: Smaller generators frequently utilize SI engines due to their compact size and reasonable fuel efficiency.

- Construction Equipment: Smaller construction tools like concrete saws, pumps, and compactors often employ SI engines for their favorable power-to-weight characteristics.

Aviation

- Light Aircraft: Many private and training aircraft use spark ignition engines, typically larger horizontally-opposed designs optimized for reliability and smooth operation.

- Ultralight Aircraft: Very small aircraft often use modified automotive or purpose-built aircraft SI engines.

Industrial Applications

- Forklifts and Small Material Handlers: SI engines running on propane or natural gas are often used in indoor applications to reduce emissions in enclosed spaces.

- Irrigation Pumps: In agricultural settings, spark ignition engines frequently power water pumps where electrical power isn’t readily available.

- Compressors: Many portable air compressors utilize SI engines for their reliability and ease of maintenance.

The versatility of spark ignition engines, particularly their ability to run on multiple fuel types including gasoline, natural gas, propane, and ethanol, has contributed to their widespread adoption across these diverse applications. While electric motors are beginning to replace SI engines in some contexts, the fundamental design continues to evolve to meet changing efficiency and emissions requirements across many industries.

What Are the Advantages Of Spark Ignition Engine?

Spark ignition engines offer numerous advantages that have sustained their position as the predominant power source for passenger cars and many other applications. These benefits span performance characteristics, practical considerations, and operational features.

High Power-to-Weight Ratio

- SI engines typically deliver more power per unit of weight compared to compression ignition engines, making them ideal for applications where weight is a critical factor, such as passenger cars and light aircraft.

- The lighter construction allows for better vehicle dynamics and handling characteristics in automotive applications.

Higher RPM Capability

- Spark ignition engines can generally operate at significantly higher rotational speeds than their diesel counterparts, enabling greater power output from smaller displacement engines.

- This high-revving capability makes them particularly suitable for performance applications where responsiveness and power density are prioritized.

Smoother and Quieter Operation

- The controlled combustion initiated by spark plugs results in a more gradual pressure rise in the cylinder, producing less vibration and noise compared to the rapid pressure spike in diesel engines.

- This refinement characteristic makes SI engines preferable for passenger vehicles where comfort is a priority.

Lower Initial Manufacturing Cost

- SI engines typically require less robust construction due to lower peak cylinder pressures, reducing material costs.

- Less sophisticated fuel injection systems are needed compared to the high-pressure systems required in modern diesel engines.

- These factors contribute to lower vehicle purchase prices, particularly important in economy car segments.

Better Cold-Start Capability

- Gasoline engines generally start more readily in cold conditions compared to diesel engines, which rely on compression heat for ignition.

- This advantage is particularly valuable in regions with severe winter conditions.

Lower Particulate Emissions

- SI engines traditionally produce fewer particulate emissions (soot) than diesel engines, though this gap has narrowed with advances in diesel technology.

- This characteristic has historically made meeting particulate emissions standards easier for gasoline-powered vehicles.

Multi-Fuel Capability

- Modern SI engines can be designed or adapted to run on various fuels including gasoline, ethanol, natural gas, propane, and hydrogen.

- This flexibility provides options for regions with different fuel availability or preferences.

Lighter Weight Systems

- The overall powertrain system, including transmission and exhaust treatment systems, is typically lighter for SI engines compared to equivalent diesel powertrains.

- This weight advantage contributes to better overall vehicle efficiency in some applications.

Superior Performance at Variable Loads

- SI engines typically respond better to rapidly changing load demands, providing smoother transitions during acceleration and deceleration.

- This characteristic makes them well-suited for stop-and-go urban driving conditions.

Lower Nitrogen Oxide Emissions

- When properly tuned, SI engines can produce lower NOx emissions than diesel engines without extensive exhaust after-treatment systems.

- This advantage has become increasingly important as emissions regulations have tightened worldwide.

These advantages explain why spark ignition engines remain the predominant choice for passenger cars despite diesel engines’ higher thermal efficiency. As automotive technology continues to evolve, many of these inherent advantages are being further enhanced through innovations like direct injection, variable valve timing, and cylinder deactivation, keeping SI engines competitive even as alternative powertrains gain market share.

What Are the Disadvantages Of Spark Ignition Engine?

Despite their widespread use and numerous advantages, spark ignition engines also present several disadvantages that engineers and manufacturers continue to address through ongoing technological developments. Understanding these limitations provides context for the evolution of automotive powertrains and the growing interest in alternative technologies.

Lower Thermal Efficiency

- SI engines typically achieve thermal efficiency in the range of 25-35%, significantly lower than the 35-45% commonly achieved by diesel engines.

- This efficiency gap translates to higher fuel consumption for equivalent power output, increasing operating costs and environmental impact.

Lower Torque at Low RPM

- Spark ignition engines generally produce less low-end torque compared to diesel engines, requiring more frequent gear changes in cars when accelerating from a standstill or climbing hills.

- This characteristic can make SI engines feel less responsive during everyday driving compared to torque-rich diesel alternatives.

Higher Fuel Consumption

- The lower thermal efficiency directly results in higher fuel consumption, particularly noticeable in highway driving scenarios.

- This disadvantage has economic implications for vehicle owners and environmental consequences through increased carbon emissions.

Risk of Knock and Pre-ignition

- SI engines face the challenge of abnormal combustion phenomena such as knock (detonation) and pre-ignition, which can cause engine damage if not properly controlled.

- These issues limit the maximum compression ratio that can be safely employed, constraining potential efficiency improvements.

Carbon Buildup in Direct Injection Systems

- Modern direct injection SI engines can experience carbon deposit accumulation on intake valves, as fuel no longer washes over the valves to keep them clean.

- These deposits can reduce performance and efficiency over time, potentially requiring specialized cleaning procedures.

Throttling Losses

- SI engines regulate power primarily by throttling the intake air, creating pumping losses that reduce efficiency, particularly at partial loads.

- These losses are especially significant during typical city driving conditions, where the engine rarely operates at full throttle.

Temperature Management Challenges

- The higher combustion temperatures in SI engines can lead to heat management challenges, potentially causing thermal stress on components.

- These temperature extremes can accelerate wear on valves, pistons, and other critical engine parts under severe operating conditions.

Higher CO2 Emissions

- The lower thermal efficiency and higher fuel consumption directly translate to increased carbon dioxide emissions per mile driven compared to diesel engines.

- This disadvantage has gained increased importance as governments worldwide implement stricter CO2 emission regulations.

Sensitivity to Fuel Quality

- SI engines can be more sensitive to fuel quality variations, and factors like octane rating and fuel composition impact performance and efficiency.

- This sensitivity can cause issues in regions where fuel quality control is less stringent.

Complex Emission Control Systems

- Modern SI engines require sophisticated emission control systems including catalytic converters, oxygen sensors, and evaporative emission controls.

- These systems add cost, complexity, and potential failure points to the overall vehicle design.

Automotive engineers continue to address these disadvantages through technologies like direct injection, turbocharging, variable compression ratio systems, and improved thermal management. Many modern SI engines have significantly narrowed the efficiency gap with diesel engines while maintaining their inherent advantages, making them likely to remain relevant in the automotive landscape for the foreseeable future, even as hybrid and electric powertrains gain market share.

FAQs About the Spark-ignition engine

Are spark ignition engines and gasoline engines the same thing?

Yes, spark ignition engines and gasoline engines typically refer to the same technology. These engines rely on spark plugs to ignite the air-fuel mixture and most commonly run on gasoline (petrol). However, spark ignition engines can also operate on alternative fuels like natural gas, propane, or ethanol while still using the same fundamental ignition principle.

How does a four-stroke SI engine differ from a two-stroke SI engine?

A four-stroke SI engine completes a full cycle in four piston movements (intake, compression, power, exhaust) requiring two complete crankshaft revolutions. A two-stroke engine completes the same cycle in just two piston movements and one crankshaft revolution by combining functions. Two-stroke engines are simpler and lighter but generally less efficient and produce more emissions than their four-stroke counterparts.

Can spark ignition engines run on diesel fuel?

No, conventional spark ignition engines cannot run on diesel fuel. Diesel has different combustion characteristics and requires the higher compression ratios found in compression ignition engines. Using diesel in a spark ignition engine would cause serious operation problems and potential engine damage. SI engines are designed specifically for more volatile fuels like gasoline that can be effectively ignited by a spark.

Which is more efficient: spark ignition or compression ignition engines?

Compression ignition (diesel) engines are generally more thermally efficient than spark ignition engines. CI engines typically achieve efficiency rates of 35-45% compared to 25-35% for SI engines. This efficiency difference stems from the higher compression ratios and unthrottled operation of diesel engines. However, modern technologies like direct injection and turbocharging are narrowing this efficiency gap in newer SI engine designs.

Why do most cars use spark ignition engines rather than diesel engines?

Most passenger cars use spark ignition engines because they offer a better balance of cost, weight, refinement, and performance characteristics suited to typical driving patterns. SI engines are generally lighter, less expensive to manufacture, operate more smoothly, produce less noise and vibration, and can achieve higher RPMs than diesel engines. These factors typically outweigh the fuel economy advantage of diesel engines for many consumers and manufacturers.

How have emissions regulations affected spark ignition engine design?

Emissions regulations have dramatically influenced SI engine evolution, driving innovations like electronic fuel injection, catalytic converters, variable valve timing, and direct injection. These technologies have significantly reduced harmful emissions while improving efficiency. Modern requirements have pushed manufacturers to develop more sophisticated engine management systems that precisely control the combustion process to minimize pollutants while maintaining performance and fuel economy.