The car engine is a complex mechanical marvel that converts fuel into the energy needed to power your vehicle. Understanding the intricate network of components within your car engine isn’t just for mechanics; it’s valuable knowledge for every driver. A fundamental grasp of automotive engines can help you communicate more effectively with mechanics, make informed maintenance decisions, and potentially save on unnecessary repairs. In this comprehensive guide, we’ll explore the essential parts of vehicle engines, examining their functions and relationships within the powertrain system.

What is a Car Engine?

A car engine, or automotive engine, is a sophisticated machine that generates mechanical power through controlled explosions. This power-generating system converts chemical energy from fuel into mechanical energy that propels your vehicle forward. At its core, a car engine is an internal combustion engine (ICE) that relies on the combustion of fuel within a confined space to create energy.

The engine consists of two primary sections: the cylinder block (the lower section containing the cylinders and crankshaft) and the cylinder head (the upper section housing the valves, spark plugs, and camshaft). These components work together in perfect harmony to create the power that drives your vehicle.

Modern vehicle engines are marvels of engineering precision, typically featuring hundreds of moving parts that must function in perfect synchronization. The cylinder block serves as the foundation, providing structural integrity and housing the pistons that move up and down. Meanwhile, the cylinder head manages the air-fuel mixture and exhaust flow through a system of valves.

Despite their complexity, all automotive engines operate on similar principles, whether they’re powering economy cars or high-performance vehicles. Understanding these principles is the first step to appreciating how your car functions and how to maintain it properly.

What does the cylinder head do in a car engine?

The cylinder head is a crucial component that sits atop the engine block, serving as the “lid” for the combustion chambers. This essential part of automotive engines performs several vital functions that directly impact your car’s performance and efficiency.

First and foremost, the cylinder head houses the intake and exhaust valves, which control the flow of air and fuel into the combustion chamber and allow exhaust gases to exit. These valves are operated by the camshaft, another critical component located either in the cylinder head (overhead cam designs) or in the engine block (pushrod designs).

Additionally, the cylinder head contains spark plugs in gasoline engines, which ignite the air-fuel mixture to create combustion. In diesel vehicle engines, the cylinder head houses fuel injectors instead. The head gasket seals the joint between the cylinder head and engine block, preventing coolant and oil leaks while maintaining proper compression.

The design of a cylinder head significantly influences an engine’s efficiency and power output. Modern cylinder heads often feature multiple valves per cylinder (typically four—two intake and two exhaust) to improve airflow and combustion efficiency. This design enhancement is one reason why today’s car engines can produce more power from smaller displacements than their predecessors.

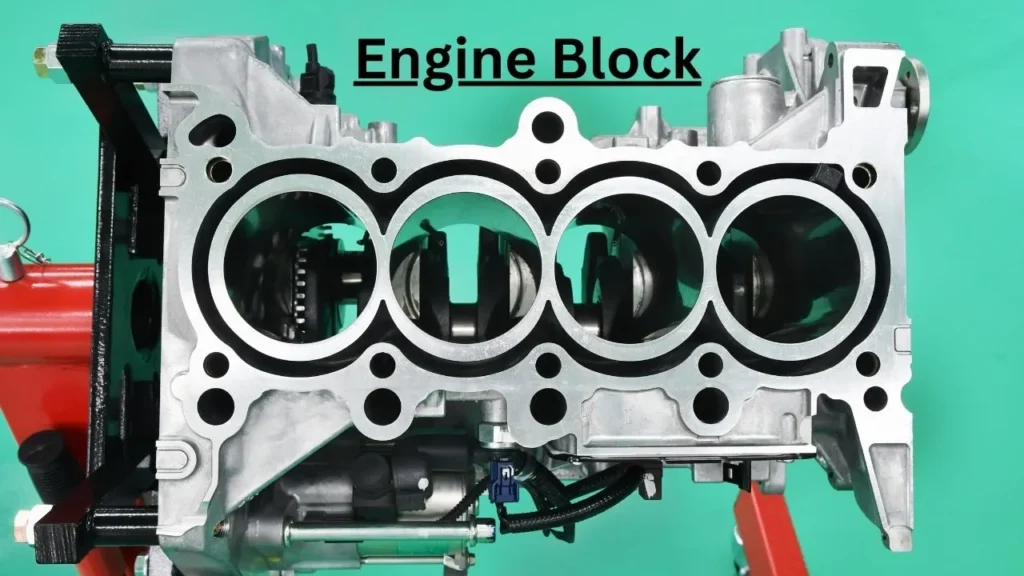

Why is the engine block important for the structure of the engine?

The engine block serves as the fundamental structural foundation of your car’s engine, making it perhaps the most crucial component in automotive engines. Often cast from aluminum alloy or iron, this massive component forms the core around which all other engine parts are assembled.

Primarily, the engine block houses the cylinders—the chambers where combustion occurs. These precisely machined cylinders contain the pistons that move up and down during the engine’s operation. The number of cylinders varies depending on the engine type, with four, six, and eight being the most common configurations in modern car engines.

Beyond containing the cylinders, the engine block features numerous channels and passages for coolant circulation. These cooling jackets surround the cylinders and help maintain optimal operating temperatures, preventing overheating that could lead to engine failure. Similarly, the block contains oil galleries that distribute lubricant to moving parts, reducing friction and wear.

The engine block also supports the crankshaft via main bearings. The crankshaft converts the pistons’ up-and-down motion into rotational motion that eventually reaches your car’s wheels. Without a sturdy, precisely manufactured engine block, this energy transfer would be impossible.

In modern automobile engineering, the choice between aluminum and iron blocks represents a careful balance between weight, strength, and heat dissipation. Aluminum blocks are lighter, improving fuel efficiency, while iron blocks offer superior durability and heat management. This selection illustrates how engine automotive design constantly evolves to meet changing performance and efficiency demands.

How Does a Car Engine Work?

Understanding how a car engine works reveals the brilliant engineering behind modern automotive transportation. At its core, a car engine operates on the principle of converting chemical energy from fuel into mechanical energy through a series of controlled explosions.

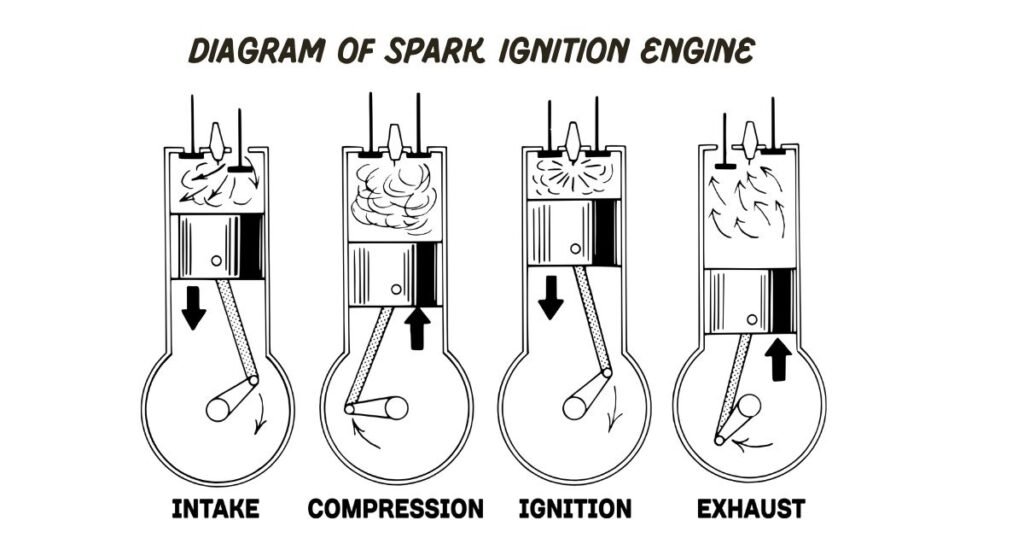

Most car engines today use the four-stroke combustion cycle, a process that repeats thousands of times per minute while your vehicle is running. Each cylinder in the engine goes through this cycle independently, creating a smooth, continuous power delivery. Let’s examine each stroke in detail:

#1. Intake Stroke

During the intake stroke, the piston moves downward while the intake valve opens. This downward movement creates a vacuum that draws a mixture of air and fuel into the cylinder. In modern automotive engines with fuel injection systems, air enters through the intake valve while fuel is sprayed directly into either the intake port or the combustion chamber. This precise mixture is crucial for efficient combustion.

#2. Compression Stroke

Once the cylinder is filled with the air-fuel mixture, the intake valve closes, and the piston moves upward, compressing the mixture into a fraction of its original volume. This compression makes the subsequent combustion more powerful and efficient. The compression ratio—typically between 8:1 and 14:1 in modern car engines—is a critical factor in determining engine performance and efficiency.

#3. Power Stroke

At the top of the compression stroke, with the air-fuel mixture highly compressed, the spark plug fires, igniting the mixture. The resulting explosion forces the piston downward, generating power that is transferred to the crankshaft. This power stroke is where chemical energy is converted to mechanical energy, providing the force that ultimately propels your vehicle.

#4. Exhaust Stroke

After the power stroke, the exhaust valve opens as the piston moves upward again, pushing out the burned gases from the cylinder into the exhaust system. Once complete, the exhaust valve closes, the intake valve opens, and the four-stroke cycle begins again.

The crankshaft, connected to the pistons via connecting rods, converts the pistons’ reciprocating motion into rotational motion. This rotation is then transferred through the transmission and drivetrain to the wheels, propelling your car forward.

Modern internal combustion engines achieve remarkable efficiency, converting about 25-30% of fuel energy into mechanical power. The remaining energy is lost as heat through the cooling system and exhaust. Engineers continually refine the combustion process to improve this efficiency, leading to more powerful yet fuel-efficient vehicles.

The entire engine system is synchronized through the timing belt or chain, which ensures that the valves open and close at precisely the right moments relative to the pistons’ positions. This intricate dance of mechanical components highlights the precision engineering behind every car engine.

Car Engine Parts Names with Diagram

Understanding the components of your car engine becomes much clearer when you can visualize how they fit together. A comprehensive engine diagram serves as an invaluable reference for both automotive enthusiasts and regular drivers. The diagram illustrates how various components—from the cylinder block to the valves, pistons, and auxiliary systems—interact to create the power that drives your vehicle.

When examining an engine diagram, you’ll notice the logical arrangement of components: the engine block forms the foundation, with the crankshaft positioned along its bottom section. The pistons connect to the crankshaft via connecting rods, while the cylinder head sits atop the block, housing the valves and camshaft. Surrounding these core components are the intake and exhaust systems, cooling apparatus, and lubrication network.

Modern car engine diagrams often highlight the differences between various engine types, such as inline, V-type, or flat configurations. Each design positions the cylinders differently, affecting the vehicle’s center of gravity, space efficiency, and vibration characteristics.

For those interested in automotive engineering, studying these diagrams reveals how engineers have optimized engine designs over decades, balancing power, efficiency, reliability, and manufacturability concerns. Whether you’re troubleshooting an issue or simply satisfying your curiosity about what’s under your hood, a comprehensive engine diagram provides valuable insight into the heart of your vehicle.

List Of 45 Car Engine Parts Names

1. Engine Block

The engine block is the main structure of the car engine that houses the cylinders and their components. Also called the cylinder block, this foundation piece is typically made from cast iron or aluminum. The engine block contains coolant passages that help manage engine temperature during operation. A well-maintained engine block can last the lifetime of your vehicle.

Symptoms of Bad Engine Block

- Visible external cracks

- Coolant mixing with engine oil

- Overheating despite proper coolant levels

- White smoke from the exhaust

Main Function of Engine Block

The engine block provides structural support for the entire engine assembly while housing the cylinders where combustion occurs.

2. Cylinder Head

The cylinder head sits atop the engine block, sealing the top of the cylinders. This component houses the combustion chambers, valves, springs, and camshafts in overhead designs. Modern cylinder heads are typically aluminum to reduce weight and improve heat dissipation.

Symptoms of Bad Cylinder Head

- White exhaust smoke

- Overheating engine

- Bubbling in radiator

- Loss of coolant without visible leaks

Main Function of Cylinder Head

The cylinder head controls the flow of air and exhaust gases while housing the combustion chamber where the air-fuel mixture ignites.

3. Pistons

Pistons are cylindrical components that move up and down within the cylinders. Connected to the crankshaft via connecting rods, pistons transfer the energy from combustion into mechanical motion. These components are typically made from aluminium alloy with specialized coatings to withstand extreme temperatures and reduce friction.

Symptoms of Bad Pistons

- Excessive white or blue smoke from exhaust

- Decreased power and acceleration

- Unusual engine noise (knocking or pinging)

- Poor fuel economy

Main Function of Pistons

Pistons harness the energy from combustion to push down on the crankshaft, creating rotational motion that powers the vehicle.

4. Connecting Rods

Connecting rods link the pistons to the crankshaft, transferring the pistons’ linear motion into the crankshaft’s rotational motion. These components must withstand tremendous forces while remaining lightweight enough to minimize inertia.

Symptoms of Bad Connecting Rods

- Loud knocking noises from the engine

- Metal shavings in the oil

- Sudden loss of power

- Engine seizure in severe cases

Main Function of Connecting Rods

Connecting rods transfer power from the pistons to the crankshaft while allowing the conversion from linear to rotational motion.

5. Crankshaft

The crankshaft is a rotating shaft that converts the pistons’ reciprocating motion into rotational motion. This precision-machined component features offset throws that connect to the connecting rods and main journals that support the shaft in the engine block.

Symptoms of Bad Crankshaft

- Excessive vibration

- Knocking noise from the lower engine

- Loss of oil pressure

- Inability to maintain idle

Main Function of Crankshaft

The crankshaft converts the pistons’ up-and-down motion into rotational motion that can be transmitted to the vehicle’s wheels.

6. Camshaft

The camshaft controls the opening and closing of the engine’s valves. Featuring precisely shaped lobes or cams, this shaft rotates in sync with the crankshaft to ensure valves open and close at the correct times during the four-stroke cycle.

Symptoms of Bad Camshaft

- Poor engine performance

- Ticking or tapping noise

- Rough idle

- Failed emissions test

Main Function of Camshaft

The camshaft precisely times the opening and closing of the intake and exhaust valves during engine operation.

7. Valves

Valves control the flow of gases in and out of the combustion chamber. Intake valves allow the air-fuel mixture to enter the chamber, while exhaust valves permit burned gases to exit. These components must withstand extreme temperatures and pressures.

Symptoms of Bad Valves

- Loss of compression

- Misfiring engine

- Poor performance

- Tapping or clicking noises

Main Function of Valves

Valves regulate the flow of air-fuel mixture into the cylinder and exhaust gases out, maintaining proper pressure within the combustion chamber.

8. Valve Springs

Valve springs return valves to their closed position after being opened by the camshaft. These precision-engineered springs maintain proper tension to ensure valves close completely without slamming shut.

Symptoms of Bad Valve Springs

- Engine misfire

- Rough idle

- Decreased power

- Valve float at high RPM

Main Function of Valve Springs

Valve springs ensure proper valve operation by returning them to the closed position after being opened by the camshaft.

9. Timing Belt/Chain

The timing belt or chain synchronizes the rotation of the crankshaft and camshaft, ensuring valves open and close at the correct time relative to piston position. This critical component prevents pistons from colliding with valves during engine operation.

Symptoms of Bad Timing Belt/Chain

- Engine won’t start

- Ticking noise from engine

- Oil leaks near the timing cover

- Poor engine performance

Main Function of Timing Belt/Chain

The timing belt/chain ensures the engine’s valves and pistons move in precise synchronization with each other.

10. Oil Pan

The oil pan serves as a reservoir for engine oil and is bolted to the bottom of the engine block. This component typically includes baffles to prevent oil sloshing during acceleration, braking, and cornering.

Symptoms of Bad Oil Pan

- Oil leaks underneath the car

- Low oil pressure warnings

- Engine damage from oil starvation

Main Function of Oil Pan

The oil pan stores engine oil when it’s not circulating through the engine and includes the oil drain plug for oil changes.

11. Oil Pump

The oil pump circulates oil throughout the engine under pressure. This critical component ensures all moving parts receive adequate lubrication, reducing friction and heat while extending engine life.

Symptoms of Bad Oil Pump

- Low oil pressure warning light

- Increased engine noise

- Overheating engine

- Premature engine wear

Main Function of Oil Pump

The oil pump maintains proper oil pressure and circulation throughout the engine’s lubrication system.

12. Fuel Injectors

Fuel injectors spray precisely measured amounts of fuel into either the intake manifold or directly into the cylinders. These electronically controlled components have replaced carburetors in modern cars, providing better fuel efficiency, lower emissions, and improved performance.

Symptoms of Bad Fuel Injectors

- Rough idle

- Poor acceleration

- Decreased fuel economy

- Failed emissions test

Main Function of Fuel Injectors

Fuel injectors deliver precisely metered amounts of fuel into the engine at exactly the right time for optimal combustion.

13. Spark Plugs

Spark plugs create the electrical spark that ignites the air-fuel mixture in gasoline engines. These components must withstand extreme heat and pressure while providing consistent spark thousands of times per minute.

Symptoms of Bad Spark Plugs

- Difficulty starting

- Engine misfire

- Poor acceleration

- Increased fuel consumption

Main Function of Spark Plugs

Spark plugs ignite the compressed air-fuel mixture in the combustion chamber, initiating the power stroke.

14. Intake Manifold

The intake manifold distributes the air-fuel mixture to each cylinder’s intake port. This component often incorporates various sensors and thermal management features to optimize engine performance across different operating conditions.

Symptoms of Bad Intake Manifold

- Coolant leaks

- Poor fuel economy

- Engine misfires

- Rough idle

Main Function of Intake Manifold

The intake manifold evenly distributes incoming air or air-fuel mixture to each cylinder.

15. Exhaust Manifold

The exhaust manifold collects exhaust gases from multiple cylinders into one pipe. Constructed to withstand extreme temperatures, this component begins the exhaust system and often includes oxygen sensors for emissions control.

Symptoms of Bad Exhaust Manifold

- Loud exhaust noise

- Decreased power

- Check engine light

- Burning smell

Main Function of Exhaust Manifold

The exhaust manifold collects exhaust gases from the cylinders and directs them into the exhaust system.

16. Water Pump

The water pump circulates coolant through the engine and radiator. Typically driven by the engine via a belt, this component ensures proper engine operating temperature is maintained during all driving conditions.

Symptoms of Bad Water Pump

- Engine overheating

- Coolant leaks

- Whining noise from front of engine

- Steam from radiator

Main Function of Water Pump

The water pump circulates coolant throughout the engine cooling system to maintain optimal operating temperature.

17. Thermostat

The thermostat regulates engine temperature by controlling coolant flow. When cold, it restricts coolant flow to help the engine warm up quickly; when hot, it opens to allow full coolant circulation.

Symptoms of Bad Thermostat

- Engine overheating or running too cold

- Fluctuating temperature gauge

- Poor heater performance

- Decreased fuel economy

Main Function of Thermostat

The thermostat regulates engine temperature by controlling coolant flow between the engine and the radiator.

18. Radiator

The radiator dissipates heat from the engine coolant into the air. Featuring thin tubes and fins to maximize surface area, this component works with the cooling fan to maintain proper engine temperature.

Symptoms of Bad Radiator

- Engine overheating

- Coolant leaks

- Discolored coolant

- Steam from under the hood

The Main Function of the Radiator

The radiator transfers heat from the engine coolant to the outside air, keeping the engine at optimal operating temperature.

19. Alternator

The alternator generates electrical power to recharge the battery and power electrical systems while the engine is running. This component converts mechanical energy from the engine into electrical energy through electromagnetic induction.

Symptoms of Bad Alternator

- Battery warning light

- Dim headlights

- Dead battery

- Electrical system failures

Main Function of Alternator

The alternator generates electrical power to run the vehicle’s electrical systems and charge the battery while the engine is running.

20. Starter Motor

The starter motor initiates engine operation by turning the flywheel. This high-torque electric motor engages with the flywheel’s teeth to rotate the crankshaft until the engine starts running under its own power.

Symptoms of Bad Starter Motor

- Clicking noise when turning the key

- Slow cranking

- The engine won’t turn over

- Grinding noise during the starting

Main Function of Starter Motor

The starter motor provides the initial rotation of the engine needed to begin the combustion process.

21. Flywheel

The flywheel stores rotational energy and helps smooth engine operation. This heavy, balanced wheel connects to the crankshaft and provides the engagement surface for the clutch in manual transmissions or torque converter in automatics.

Symptoms of Bad Flywheel

- Vibration during clutch engagement

- Difficulty shifting gears

- Clutch slippage

- Burning smell during acceleration

Main Function of Flywheel

The flywheel maintains engine momentum between power strokes and provides a mounting surface for the starter ring gear.

22. Head Gasket

The head gasket seals the joint between the engine block and cylinder head. This critical component prevents coolant and oil from mixing while maintaining proper compression in each cylinder.

Symptoms of Bad Head Gasket

- White exhaust smoke

- Bubbles in radiator

- Oil contaminated with coolant

- Overheating engine

Main Function of Head Gasket

The head gasket seals the combustion chambers while keeping oil and coolant passages separate between the block and the head.

23. Piston Rings

Piston rings seal the gap between pistons and cylinder walls. These specialized rings prevent combustion gases from entering the crankcase, control oil consumption, and help transfer heat from the pistons to the cylinder walls.

Symptoms of Bad Piston Rings

- Blue exhaust smoke

- Loss of power

- Poor fuel economy

- Failed compression test

Main Function of Piston Rings

Piston rings seal the combustion chamber, control oil consumption, and transfer heat from the piston to the cylinder wall.

24. Fuel Pump

The fuel pump delivers fuel from the tank to the engine. Modern vehicles typically use electric pumps mounted in the fuel tank, providing consistent pressure regardless of engine speed.

Symptoms of Bad Fuel Pump

- Engine sputtering at high speeds

- Difficulty starting

- Loss of power under load

- Engine stalling

Main Function of Fuel Pump

The fuel pump delivers fuel from the tank to the fuel injectors at the pressure required for proper engine operation.

25. Air Filter

The air filter prevents dust, debris, and contaminants from entering the engine. This replaceable component ensures only clean air reaches the combustion chambers, protecting internal engine components from abrasive particles.

Symptoms of Bad Air Filter

- Reduced engine performance

- Poor fuel economy

- Black exhaust smoke

- Unusual engine sounds

Main Function of Air Filter

The air filter prevents harmful particles from entering the engine while allowing sufficient airflow for combustion.

26. Throttle Body

The throttle body controls airflow into the engine. Operated by the accelerator pedal, this component features a butterfly valve that opens and closes to regulate the amount of air entering the engine, directly affecting power output.

Symptoms of Bad Throttle Body

- Rough or high idle

- Stalling

- Hesitation during acceleration

- Check engine light

Main Function of Throttle Body

The throttle body controls the amount of air entering the engine in response to driver input via the accelerator pedal.

27. EGR Valve

The Exhaust Gas Recirculation (EGR) valve reduces nitrogen oxide emissions by recirculating some exhaust gases back into the intake manifold. This lowers combustion temperatures, which helps control emissions.

Symptoms of Bad EGR Valve

- Rough idle

- Stalling

- Failed emissions test

- Knocking or pinging sounds

Main Function of EGR Valve

The EGR valve recirculates a portion of exhaust gases back into the combustion chamber to reduce harmful emissions.

28. Oxygen Sensor

Oxygen sensors monitor the oxygen content in exhaust gases. These sensors provide feedback to the engine control unit, allowing it to adjust the air-fuel mixture for optimal performance and emissions.

Symptoms of Bad Oxygen Sensor

- Check engine light

- Poor fuel economy

- Rough idle

- Failed emissions test

Main Function of Oxygen Sensor

The oxygen sensor monitors exhaust gases to help the engine computer maintain the optimal air-fuel ratio.

29. Exhaust Pipe

The exhaust pipe channels exhaust gases from the manifold through the catalytic converter and muffler before releasing them into the atmosphere. This system reduces noise and harmful emissions while minimizing back pressure.

Symptoms of Bad Exhaust Pipe

- Excessive noise

- Exhaust leaks

- Reduced power

- Odor in vehicle cabin

Main Function of Exhaust Pipe

The exhaust pipe directs exhaust gases from the engine to the rear of the vehicle while allowing for emissions treatment.

30. Catalytic Converter

The catalytic converter reduces harmful emissions through chemical reactions. This emissions control device converts carbon monoxide, hydrocarbons, and nitrogen oxides into less harmful compounds before they exit the tailpipe.

Symptoms of Bad Catalytic Converter

- Check engine light

- Reduced performance

- Failed emissions test

- Sulfur or rotten egg smell

Main Function of Catalytic Converter

The catalytic converter converts harmful pollutants in exhaust gases into less harmful substances before they exit the tailpipe.

31. Muffler

The muffler reduces engine noise to acceptable levels. Using a series of chambers and baffles, this component cancels out sound waves while minimizing restriction to exhaust flow.

Symptoms of Bad Muffler

- Excessive noise

- Rust or holes in the muffler body

- Decreased fuel efficiency

- Exhaust fumes in the cabin

The Main Function of a Muffler

The muffler reduces engine noise by cancelling sound waves in the exhaust system.

32. Turbocharger/Supercharger

Turbochargers and superchargers increase engine power by forcing more air into the cylinders. While turbochargers use exhaust energy and superchargers use mechanical energy from the crankshaft, both allow smaller engines to produce more power efficiently.

Symptoms of Bad Turbocharger

- Loss of power

- Excessive smoke

- Whining or whistling noise

- Oil leaks

Main Function of Turbocharger/Supercharger

Turbochargers and superchargers increase engine power by forcing more air into the combustion chambers.

33. Mass Airflow Sensor

The mass airflow sensor measures the amount of air entering the engine. This electronic component provides critical data to the engine control unit for calculating proper fuel delivery.

Symptoms of Bad Mass Airflow Sensor

- Rough idle

- Stalling

- Hesitation during acceleration

- Poor fuel economy

Main Function of Mass Airflow Sensor

The mass airflow sensor measures the volume and density of air entering the engine to help determine the correct fuel mixture.

34. Fuel Pressure Regulator

The fuel pressure regulator maintains consistent fuel pressure to the injectors. This component ensures optimal fuel delivery across varying engine loads and speeds.

Symptoms of Bad Fuel Pressure Regulator

- Poor starting

- Fuel leaks

- Black exhaust smoke

- Engine misfire

Main Function of Fuel Pressure Regulator

The fuel pressure regulator maintains the correct fuel pressure for proper engine operation across all conditions.

35. Crankshaft Position Sensor

The crankshaft position sensor monitors the crankshaft’s position and rotational speed. This information is crucial for ignition timing and fuel injection sequencing.

Symptoms of Bad Crankshaft Position Sensor

- Engine stalling

- Starting difficulties

- Random misfires

- Check engine light

Main Function of Crankshaft Position Sensor

The crankshaft position sensor provides information about the crankshaft position and engine speed to the engine control module.

36. Camshaft Position Sensor

The camshaft position sensor tracks the camshaft’s rotation. This information helps the engine control unit determine which cylinder is ready for fuel injection and ignition, especially in sequential fuel injection systems.

Symptoms of Bad Camshaft Position Sensor

- Engine hesitation

- Starting problems

- Poor acceleration

- Reduced fuel economy

Main Function of Camshaft Position Sensor

The camshaft position sensor informs the engine computer about valve timing for precise fuel injection and ignition timing.

37. Engine Control Unit (ECU)

The Engine Control Unit is the computer that manages engine operation. This sophisticated electronic controller processes information from various sensors to optimize fuel delivery, ignition timing, and other parameters for best performance, economy, and emissions.

Symptoms of Bad ECU

- Check engine light

- Engine running rich or lean

- Poor performance

- Failure to start

Main Function of ECU

The ECU processes information from various sensors to control fuel injection, ignition timing, and other engine functions.

38. Valve Lifters

Valve lifters transfer motion from the camshaft to the valves. These components, also called tappets, may be mechanical or hydraulic. Hydraulic lifters automatically adjust to maintain zero valve clearance.

Symptoms of Bad Valve Lifters

- Ticking noise from the engine

- Misfiring

- Poor performance

- Check engine light

Main Function of Valve Lifters

Valve lifters transfer motion from the camshaft lobes to the valves, maintaining proper valve clearance.

39. Oil Filter

The oil filter removes contaminants from engine oil. This replaceable component prevents abrasive particles from circulating through the engine, protecting bearings and other precision components from premature wear.

Symptoms of Bad Oil Filter

- Low oil pressure

- Dirty oil

- Engine overheating

- Metallic noises from the engine

Main Function of Oil Filter

The oil filter removes contaminants from engine oil to protect internal engine components from wear.

40. Rocker Arms

Rocker arms transfer motion from the camshaft (or pushrod) to the valves. These lever mechanisms can amplify the lifting motion, allowing for greater valve lift than the cam lobe alone provides.

Symptoms of Bad Rocker Arms

- Ticking noise

- Loss of power

- Poor fuel economy

- Failed emissions test

Main Function of Rocker Arms

Rocker arms transfer and multiply camshaft motion to operate the engine’s valves.

41. Throttle Position Sensor

The throttle position sensor monitors the throttle valve’s position. This sensor informs the engine control unit about driver demand, allowing for appropriate adjustments to fuel delivery and ignition timing.

Symptoms of Bad Throttle Position Sensor

- Sudden idle changes

- Hesitation during acceleration

- Stalling

- Poor fuel economy

Main Function of Throttle Position Sensor

The throttle position sensor informs the engine computer about the throttle position for proper fuel and timing adjustments.

42. PCV Valve

The Positive Crankcase Ventilation valve recirculates crankcase gases back into the intake. This emissions control device prevents pressure buildup in the crankcase while reducing hydrocarbon emissions.

Symptoms of Bad PCV Valve

- Oil leaks

- Excessive oil consumption

- Rough idle

- Check engine light

Main Function of PCV Valve

The PCV valve recirculates crankcase vapours back into the intake system to reduce emissions and prevent pressure buildup.

43. Timing Cover

The timing cover protects the timing belt or chain. This component shields the timing system from debris while containing oil in chain-driven systems.

Symptoms of Bad Timing Cover

- Oil leaks

- Contamination of timing components

- Unusual noise from the timing area

- Engine overheating

Main Function of Timing Cover

The timing cover protects the timing belt or chain from debris and contains oil in chain-driven systems.

44. Engine Bearings

Engine bearings support rotating components like the crankshaft and connecting rods. These precision-machined components reduce friction while handling tremendous loads during engine operation.

Symptoms of Bad Engine Bearings

- Low oil pressure

- Knocking noises

- Metal particles in the oil

- Reduced power

Main Function of Engine Bearings

Engine bearings support rotating components while minimizing friction and wear.

45. Camshaft Bearings

Camshaft bearings support the camshaft within the engine block or cylinder head. These specialized bearings allow the camshaft to rotate freely while withstanding side loads from valve actuation.

Symptoms of Bad Camshaft Bearings

- Ticking noise from the upper engine

- Poor performance

- Oil pressure fluctuations

- Metal in oil

Main Function of Camshaft Bearings

Camshaft bearings support the camshaft while allowing it to rotate with minimal friction.

What is the difference between a vehicle engine and a motor car engine?

When discussing automotive engines, the terms “vehicle engine” and “motor car engine” are often used interchangeably, but there are subtle distinctions worth understanding. Here’s a comparison of these terms:

| Aspect | Vehicle Engine | Motor Car Engine |

| Definition | A broader term that encompasses engines for all vehicle types, including cars, trucks, buses, and motorcycles | Specifically refers to engines designed for passenger automobiles |

| Application Range | Used in various transportation vehicles from light to heavy-duty | Primarily designed for personal transportation vehicles |

| Design Considerations | Varies widely based on vehicle type and purpose | Optimized for passenger comfort, fuel economy, and moderate performance |

| Power Output | Ranges from small motorcycle engines to massive truck engines | Typically ranges from 50hp to 600hp in standard passenger cars |

| Fuel Types | Includes specialized fuels for commercial vehicles | Predominantly gasoline or diesel with increasing hybrid and electric options |

| Regulatory Focus | Subject to category-specific regulations | Subject to passenger car emissions and safety standards |

While the fundamental operating principles remain the same for both terms, the distinction matters when discussing specific applications, designs, and engineering considerations. In everyday conversation, however, these terms are functionally equivalent when referring to the power plant in your personal automobile.

What is the importance of engine oil in maintaining car engine parts?

Engine oil is the lifeblood of automotive engines, crucially ensuring the optimal performance and longevity of numerous engine parts. This vital fluid performs several essential functions that directly impact the health of car engine components.

Engine oil primarily provides lubrication to moving parts, creating a protective film between metal surfaces that would otherwise generate excessive friction and heat. This lubrication is particularly critical for components like pistons, connecting rods, crankshafts, and camshafts that experience constant motion and stress. Without proper lubrication, these automotive parts would rapidly wear down, leading to decreased performance and potentially catastrophic engine failure.

Beyond lubrication, engine oil serves as a cooling agent for components that don’t directly benefit from the car’s cooling system. As it circulates through the engine, the oil absorbs heat from parts like the underside of pistons and bearings, helping maintain optimal operating temperatures throughout the engine.

Modern engine oils also contain detergents and dispersants that clean engine parts by preventing the buildup of sludge, varnish, and carbon deposits. If allowed to accumulate, these contaminants can restrict oil flow, clog critical passages, and interfere with proper component function.

Additionally, quality engine oils contain additives that neutralize acids formed during combustion, preventing corrosion of vital engine components. This acid neutralization protects metal surfaces throughout the engine from chemical degradation.

Regular oil changes are essential because engine oil degrades over time, losing its protective properties. Fresh oil ensures that all engine parts receive maximum protection, cooling, and cleaning benefits, directly contributing to the longevity of your vehicle’s powertrain.

What is the role of the catalytic converter in the exhaust system?

The catalytic converter plays a pivotal role in modern vehicle engines by transforming harmful exhaust emissions into less damaging substances before they enter the atmosphere. Located between the engine and the muffler in the exhaust system, this critical component contains precious metals—typically platinum, palladium, and rhodium—embedded in a ceramic honeycomb structure.

As hot exhaust gases flow through the catalytic converter, these precious metals act as catalysts, triggering chemical reactions that convert three primary pollutants: carbon monoxide (CO), nitrogen oxides (NOx), and unburned hydrocarbons (HC). Through oxidation and reduction processes, carbon monoxide becomes carbon dioxide, nitrogen oxides are reduced to nitrogen and oxygen, and hydrocarbons are converted to carbon dioxide and water vapour.

Modern automotive engines rely on catalytic converters to meet increasingly stringent emissions regulations worldwide. A properly functioning “cat” can eliminate over 90% of harmful emissions from car engine exhaust. The catalytic converter works most efficiently at high temperatures, typically above 600°F (315°C), which is why emissions are higher when engines are cold.

In addition to environmental benefits, catalytic converters help optimize engine performance. By working in conjunction with oxygen sensors and the engine control module, they ensure the proper air-fuel ratio is maintained for efficient combustion in the engine cylinders. This helps vehicle engines achieve better fuel economy while maintaining power output.

Signs of a failing catalytic converter include decreased engine performance, reduced fuel efficiency, a rotten egg smell, and illumination of the check engine light. Regular engine maintenance—including proper fuel mixture, timely spark plug replacement, and addressing oil leaks—helps extend catalytic converter life in car engines by preventing contamination of its catalytic surfaces.

What is the difference between turbocharging and supercharging in car engines?

Turbocharging and supercharging are two distinct forced induction methods that enhance car engine performance, though they operate on different principles.

A turbocharger uses exhaust gases to spin a turbine, which drives a compressor that forces additional air into the engine’s combustion chambers. This recycling of exhaust energy makes turbochargers more fuel-efficient. However, turbocharged engines often experience “turbo lag” – a delay between pressing the accelerator and feeling the power boost.

In contrast, a supercharger is mechanically driven by the car engine itself, typically via a belt connected to the crankshaft. This direct connection eliminates lag, providing immediate power delivery. The drawback is that superchargers consume some engine power to operate, making them less fuel-efficient than turbochargers.

Both systems increase engine power without enlarging cylinder displacement, allowing smaller, more efficient engines to produce performance comparable to naturally aspirated larger engines. This technology is increasingly important in modern automotive engineering as manufacturers seek to balance power with fuel economy and reduced emissions.

What are common car engine problems and how can they be fixed?

Car engines can develop various issues over time, with several recurring problems that vehicle owners should be aware of:

Overheating

Overheating often stems from cooling system failures. Check for low coolant levels, leaking radiator hoses, faulty water pumps, or malfunctioning thermostats. Regular coolant flushes and maintaining proper fluid levels can prevent many overheating issues in car engines.

Oil Leaks

Engine oil leaks typically occur around deteriorated gaskets and seals. Common sources include the valve cover gasket, oil pan gasket, and rear main seal. Replacing the affected gaskets or seals is the proper fix, though some minor leaks can be temporarily managed with stop-leak additives in automotive engines.

Engine Misfires

Misfires create rough running conditions and reduced power. They’re commonly caused by worn spark plugs, damaged ignition coils, clogged fuel injectors, or vacuum leaks. The appropriate solution for vehicle engines is to diagnose the specific cylinder experiencing the misfire and replace the affected components.

Poor Fuel Economy

When a car engine consumes excessive fuel, check for dirty air filters, malfunctioning oxygen sensors, or improper tire pressure. Regular maintenance including air filter replacement and keeping tyres properly inflated can significantly improve fuel economy in motor car engines.

Knocking Sounds

Engine knocking often indicates serious internal problems such as worn bearings, damaged pistons, or improper fuel octane. Early attention is crucial to prevent catastrophic engine failure. Using the manufacturer-recommended fuel grade and maintaining proper oil levels can help prevent knock-in engine automotive systems.

Rough Idling

A car that shakes or vibrates while idling might have dirty fuel injectors, a clogged air filter, or a vacuum leak. Carbon buildup in the throttle body can also cause rough idling. Regular fuel system cleanings and air filter replacements help maintain smooth idle performance.

Check Engine Light

The check engine light illuminates when the engine control module detects an issue. Use an OBD-II scanner to retrieve the specific error code. While some codes indicate minor issues like a loose gas cap, others might signal serious problems requiring immediate attention to engine car parts.

Preventative maintenance remains the best strategy for avoiding these common problems. Regular oil changes, fluid checks, and timely replacement of worn items like belts and filters can significantly extend engine life and prevent costly repairs to critical car engine parts.

Conclusion: Why is it essential to understand the parts of a car engine?

Understanding the components of automobile engines empowers vehicle owners in multiple ways. Knowledge of engine parts helps drivers interpret warning signs before they escalate into major failures. When that check engine light illuminates, basic automotive knowledge can help determine whether it’s a minor issue or something requiring immediate professional attention.

The financial benefits are also substantial. While complex repairs should be left to professionals, understanding engine components allows car owners to perform basic maintenance tasks independently. Oil changes, air filter replacements, and spark plug services become approachable DIY projects, saving hundreds in annual maintenance costs.

Familiarity with automobile engine components provides protection against unnecessary services when visiting repair shops. A basic understanding of car engines enables more informed conversations with mechanics and helps evaluate whether recommended repairs are truly necessary.

Beyond the practical aspects, knowledge of engine parts fosters a deeper connection between drivers and their vehicles. Understanding the intricate dance of pistons, valves, and crankshafts that powers your journey creates aan ppreciation for automotive engineering.

As vehicle technology evolves toward electrification, even electric cars contain components derived from traditional engines. The cooling systems, power transmission elements, and many other parts of engine history continue in modern electric vehicles. This knowledge remains relevant even as automotive technology advances.

Whether you’re a car enthusiast or simply a practical owner seeking reliability, understanding the fundamental parts of vehicle engines provides valuable knowledge that enhances the driving experience and protects your investment. The car engine, with its precisely engineered components working in harmony, remains one of humanity’s most impactful mechanical achievements.

FAQ’s

What Is an Engine?

An engine is a mechanical device that converts fuel energy into mechanical energy to generate power. In cars, the most common type is the internal combustion engine, which burns fuel inside combustion chambers to drive pistons that turn the crankshaft. This engine ultimately powers the vehicle’s wheels through the transmission system.

How Does a Car Engine Work?

A car engine works through a four-stroke cycle: intake (drawing fuel-air mixture into cylinders), compression (compressing this mixture), power (igniting the mixture to drive pistons downward), and exhaust (expelling spent gases). This cyclical process creates rotational force that’s transferred through the drivetrain to move the vehicle.

What are the different parts of an engine?

The different parts of an automobile engine include the engine block (containing cylinders), cylinder head (housing valves and spark plugs), pistons, crankshaft, camshaft, connecting rods, timing belt/chain, fuel injection system, intake/exhaust manifolds, and various sensors. Each component in car engines serves a specific function in the power generation process.

How many parts are in a car engine?

A typical modern car engine contains approximately 250-300 individual parts, though the exact count varies by engine type and complexity. From major components like the engine block and cylinder head to smaller elements like bearings, gaskets, and sensors, these car engine parts work together in a precisely engineered system.

What Engine Does My Car Have?

You can identify your car engine type by checking the vehicle identification number (VIN), looking at the engine code stamped on the block, consulting your owner’s manual, or searching your car’s specifications online using the make, model, and year. Modern vehicles often have engine information accessible through the car’s diagnostic system.

What are the main parts of a car engine?

The main parts of a car engine include the engine block (the foundation housing the cylinders), cylinder head (containing valves and spark plugs), pistons (moving up and down within cylinders), crankshaft (converting reciprocating motion to rotation), camshaft (controlling valve operation), connecting rods (linking pistons to crankshaft), timing system, intake/exhaust systems, and the lubrication system. These components of automobile engine systems work together to generate power for vehicle propulsion.

What is the purpose of the crankshaft in a car engine?

The crankshaft is the backbone of a car engine’s power transfer system. It converts the linear up-and-down motion of the pistons into rotational force that can be transmitted to the wheels. As pistons move during combustion, they push connecting rods that turn the crankshaft. This precisely balanced component rotates within the engine block, supported by main bearings that allow smooth operation while handling tremendous forces. The crankshaft’s throws (offset portions) determine the engine’s firing order and are precisely engineered to ensure optimal balance and power delivery throughout the RPM range.

What role does the camshaft play in the engine’s functioning?

The camshaft orchestrates the critical valve operation in car engines. Its lobed design opens and closes the intake and exhaust valves with precise timing relative to the piston position. In automotive engines, this carefully choreographed sequence allows the intake of the air-fuel mixture and the expulsion of exhaust gases. Modern car engines often feature variable valve timing systems that adjust camshaft position for optimal performance across different engine speeds. The camshaft’s profile (shape and size of lobes) significantly impacts engine characteristics, determining whether an engine delivers low-end torque or high-RPM power.

What is the function of the pistons in a car engine?

Pistons are the primary moving components within engine cylinders that harness combustion energy. These cylindrical parts move up and down, creating the compression necessary for efficient combustion while capturing the explosive force from ignition. Connected to the crankshaft via connecting rods, pistons in car engines convert the pressure from burning fuel into mechanical motion. Modern automotive pistons are engineering marvels, designed to withstand extreme temperatures, maintain tight cylinder seals with piston rings, and operate reliably for hundreds of thousands of miles while moving at incredible speeds.

What does the timing belt do in a car engine?

The timing belt (or timing chain in many modern engines) synchronizes the rotation of the crankshaft and camshaft(s) to ensure valves open and close at the precise moments relative to piston position. This critical component ensures that intake valves open as pistons move downward during the intake stroke and exhaust valves open during the exhaust stroke. In interference engines, a timing belt failure can cause catastrophic engine damage as pistons may collide with open valves. Regular replacement at manufacturer-specified intervals is essential maintenance for vehicle engines with timing belts.

What impact does engine size have on car performance?

Engine size, measured in displacement (litres or cubic centimetres), significantly affects vehicle performance characteristics. Larger engines typically produce more power and torque, enabling faster acceleration and higher towing capacity. However, they generally consume more fuel. Smaller engines offer better fuel economy but may provide less robust performance unless enhanced with technologies like turbocharging or supercharging. Modern automotive engineering trends favor smaller, more efficient engines boosted with forced induction to deliver power comparable to larger naturally aspirated engines while maintaining fuel efficiency. Engine size must be balanced with vehicle weight, intended use, and efficiency goals.

How does an automotive engine convert fuel into energy?

An automotive engine converts fuel energy into mechanical energy through controlled combustion. The process begins when fuel mixes with air in precise ratios. In gasoline engines, spark plugs ignite this mixture, while diesel engines use compression-induced heat for ignition. The resulting explosion forces pistons downward, rotating the crankshaft. This chemical-to-mechanical energy conversion occurs thousands of times per minute. Only about 20-35% of fuel energy becomes useful work in typical car engines, with the remainder dissipated as heat. Advanced technologies like direct injection, variable valve timing, and turbocharging continue to improve this conversion efficiency in modern engines.

Why is a cooling system essential for car engine performance?

A cooling system is vital because internal combustion engines operate efficiently within a narrow temperature range. Without proper cooling, excessive heat would cause metal components to expand beyond tolerances, leading to seized bearings, warped cylinder heads, or blown head gaskets. The cooling system in car engines circulates coolant through passages in the engine block and cylinder head, absorbing heat before releasing it through the radiator. Maintaining optimal operating temperature also ensures proper oil viscosity, efficient combustion, and reduced emissions. Modern automotive cooling systems are pressurized to raise the boiling point of coolant and often incorporate precise electronic control for optimal engine performance.

How does the ignition system in a car engine work?

The ignition system provides the spark that ignites the compressed air-fuel mixture in gasoline engines. Modern car engines typically use electronic ignition systems where the engine control module determines optimal spark timing based on numerous sensor inputs. The process begins with the battery supplying voltage to the ignition coil, which transforms it from 12 volts to the thousands of volts needed for spark generation. This high voltage travels through spark plug wires (or directly to coil-on-plug systems) to the spark plugs, creating a precisely timed spark in each cylinder. Proper ignition timing is crucial for engine performance, fuel economy, and emissions control in automotive engines.

What are the differences between hybrid and traditional combustion car engines?

Hybrid engines combine internal combustion engines with electric motors, while traditional engines rely solely on fossil fuel combustion. In hybrid systems, the gasoline engine can be smaller and more efficient since it shares propulsion duties with electric components. Hybrids recover energy during braking through regenerative systems that traditional engines waste as heat. They typically feature start-stop technology that shuts off the combustion engine when idle. Traditional car engines provide consistent performance without battery constraints but consume more fuel, especially in city driving. Hybrid systems add complexity and weight but deliver significantly better fuel economy and reduced emissions. The balance between engine and electric power varies across different hybrid designs, from mild hybrids to plug-in systems.